Conductive & Static Dissipative Floor Tile

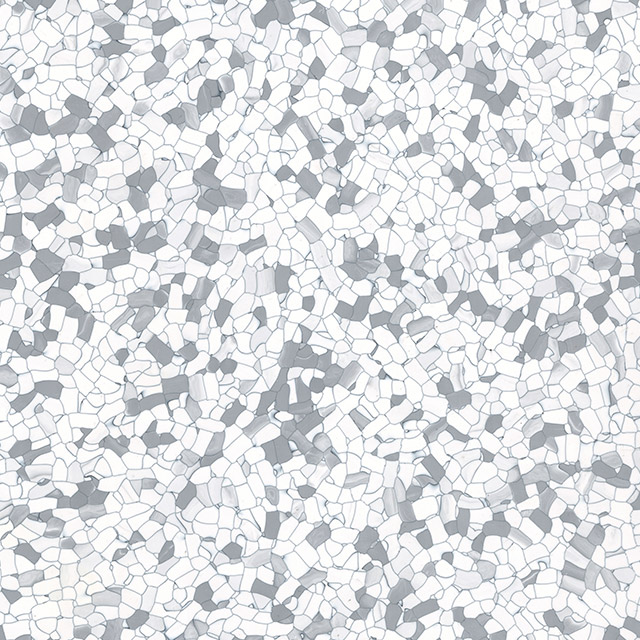

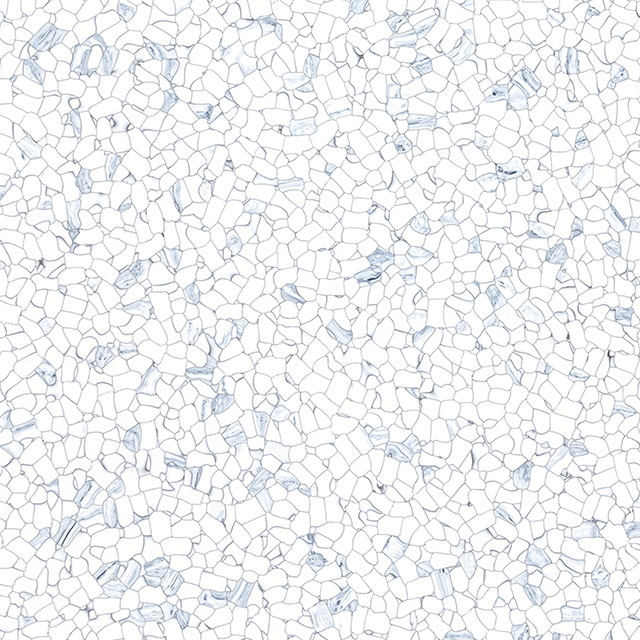

ES-1001

ES-1002

ES-1003

ES-1004

ES-1005

ES-1006

| Description | ||

| Product Name | ES - Conductive Tiles | |

| Dimension | Size : 2mm, 3mm × 600, 610, 590mm Composition : Homogeneous(Uniformity) |

|

| Production method: Extrusion + Pressing + Skiving | ||

| Key Features | The pattern is uniform and has a reticular structure Electrical resistance value is very stable |

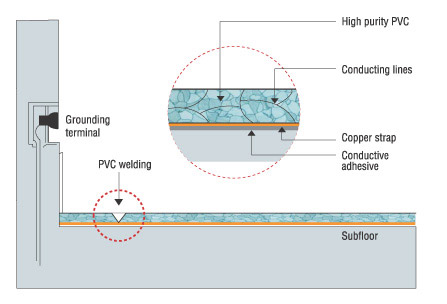

With the extrusion pellet manufacturing method, the chip shape is very uniform, and the electrical resistance is stable. (Carbon lines are connected in all directions in a net-like structure) |

| High resin content Comfortable to walk and strong against impact |

Relatively strong impact resistance due to high resin content No bending or breakage of the product (especially in winter season) |

|

| Using fine fillers Smooth surface |

High-quality fillers are used Less discoloration and smooth surface with small particles of filler |

|

| Use of water-based conductive adhesives | Eco-friendly and stable electrical resistance is maintained (solvent free) by using water-based acrylic adhesive (carbon fiber) | |

| Slight dichroism and slight discoloration | Fine color change due to the use of high-quality raw materials | |

1) The perpendicularity is the data measured in our laboratory.

| Test items | Unit | KS reference value | Test Results | Note | |

| ES Conductivity | |||||

| Electrical resistance(10V) | Surface resistance(×106Ω) | Ω | 1.0×106Below | 0.67 | Measured by ASTM F150 method Resistance value of static dissipative tile(1.0×109Ω) |

| Grounding resistance(×106Ω) | Ω | 0.43 | |||

| Electrical resistance(100V) | Surface resistance(×106Ω) | Ω | 0.36 | ||

| Grounding resistance(×106Ω) | Ω | 0.28 | |||

| Abrasion resistance (CS-17, 1,000 wears) | ㎎ | - | 117 | Higher strength to withstand load due to press working (Excellent durability and abrasion resistance) KS M 3802 standard |

|

| Amount of indentation | 20℃ | mm | 0.25 Above | 0.45 | |

| 45℃ | mm | 1.20 Below | 0.60 | ||

| Residual indentation rate | % | 8.0 Below | 5.7 | ||

| Perpendicularity | mm | 0.25 Below | 0.071) | ||

| Length change rate by heating (length) | % | 0.25 Below | 0.03 | ||

| Weight loss by heating | % | 0.5 Below | 0.2 | ||

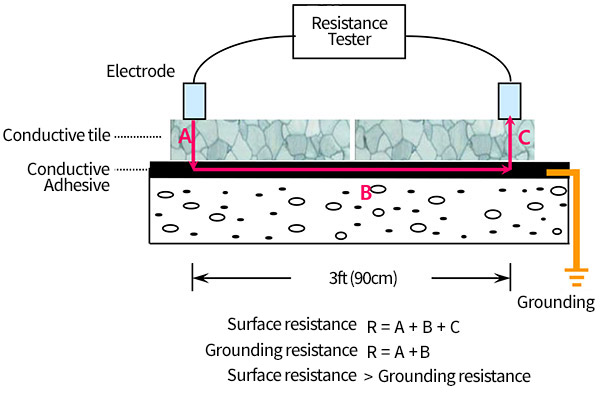

1) Conductive resistance standard is measured according to ASTM standard.

2) Measure at least 5 places on the installed floor and mark the resistance value with the average value.

Measuring Equipment SpecificationsResistance test instrument

Rated output voltage 100V or 10V DC

Short - circuit current는 2.5mA ~ 10mA

Electrode

Diameter : 64mm, Weight : 2.3kg/piece, Material : steel

Rubber pad : ø64mm, hardness A durometer 40 ~ 60

Aluminum foil : thickness 0.013mm ~ 0.025mm

| Test Method | ASTM F-150, DIN51953, ESD 7.1 | |||

| Measured voltage | 100V | 10V | ||

| Resistance standard(Ω) | Conductive | Surface-Surface resistance | 2.5 × 104 ~ 1.0 × 106 | 2.5 × 104 ~ 1.0 × 106 |

| Grounding resistance | 2.5 × 104 Above | 2.5 × 104 Above | ||

| Dissipative | Surface-Surface resistance | 1.0 × 106 ~ 1.0 × 109 | 1.0 × 106 ~ 1.0 × 109 | |

| Grounding resistance | 1.0 × 106 Above | 1.0 × 106 Above | ||